Why many industries trust Precision aluminum casting for reliable components

Wiki Article

The Function of Light Weight Aluminum Foundries in Advancing Lightweight Manufacturing Solutions

Light weight aluminum foundries significantly add to the advancement of lightweight manufacturing solutions. Their ingenious spreading modern technologies produce high-strength, lightweight elements necessary for markets such as automotive and aerospace. This advancement not just enhances product performance however also advertises sustainability via using recycled materials. As these foundries adapt to arising methods and modern technologies, they lead the way for future growths in making efficiency and environmental obligation. What exists in advance in this transformative trip?The Benefits of Lightweight Materials in Manufacturing

As markets increasingly look for performance and sustainability, the fostering of light-weight materials in manufacturing has become a vital technique - Aluminum Foundry. These materials, particularly aluminum and composites, provide many benefits that boost production procedures and item performance. Primarily, their lowered weight adds to lower energy consumption throughout transportation and procedure, leading to substantial expense savingsLight-weight products help with the design of more facility geometries, permitting for higher advancement in item development. This adaptability often results in improved capability and efficiency, accommodating the evolving needs of contemporary consumers.

Additionally, the usage of light-weight materials can enhance the long life of products as a result of their resistance to deterioration and tiredness. This sturdiness not only reduces upkeep expenses but also sustains sustainability efforts, as longer-lasting products add to less waste. To sum up, the benefits of lightweight products are critical in driving performance, technology, and ecological responsibility in production.

Advancements in Aluminum Spreading Technologies

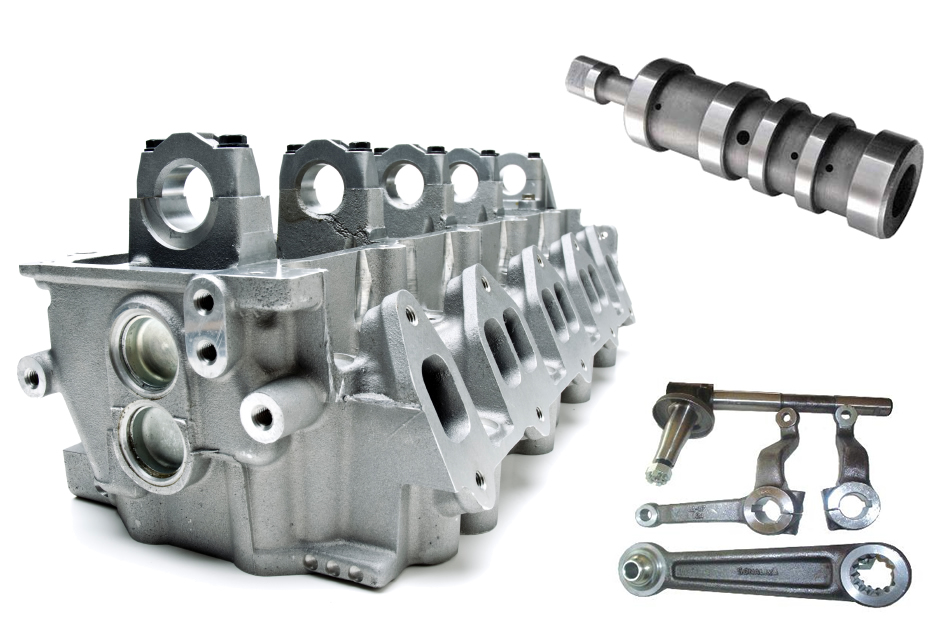

Recent innovations in light weight aluminum spreading modern technologies are revolutionizing the manufacturing landscape, especially in the manufacturing of light-weight parts. Innovations such as high-pressure die spreading and vacuum pass away spreading have actually significantly boosted the accuracy and surface area coating of light weight aluminum parts - aluminum casting. These approaches permit the production of complex geometries while decreasing material waste and improving mechanical properties

Additionally, the application of real-time tracking systems ensures quality assurance throughout the spreading process, bring about even more consistent item outcomes. Jointly, these innovations not just boost the performance of light weight aluminum elements but also support the market's change towards even more lasting manufacturing techniques.

Applications of Light Weight Aluminum Components in Different Industries

While light weight aluminum elements have long been made use of in different industries, their flexibility and lightweight properties remain to drive ingenious applications across sectors such as auto, aerospace, and building. In the automobile industry, light weight aluminum is progressively used for engine blocks, wheels, and body panels, boosting fuel efficiency and efficiency. Aerospace makers take advantage of aluminum for aircraft structures and components, profiting from its strength-to-weight proportion to boost fuel economic climate and haul ability.In the building field, aluminum is favored for window frames, roof covering, and structural elements, providing resilience and resistance to corrosion while lowering general building weight. Additionally, the electric and electronic devices markets take advantage of aluminum's conductivity and lightweight nature, utilizing it in circuitry, enclosures, and heat sinks. These diverse applications highlight the essential role of aluminum elements, which not just meet sector demands but likewise add to innovations in item design and capability across multiple fields.

Sustainability and Energy Performance in Aluminum Foundries

The aluminum foundry industry plays a vital role in promoting sustainability and energy effectiveness, specifically as need for light-weight components proceeds to grow throughout numerous sectors. Factories are significantly embracing eco friendly techniques, such as utilizing recycled aluminum, which greatly reduces power usage and greenhouse gas exhausts contrasted to key light weight aluminum manufacturing.Advancements in casting technologies boost power performance by maximizing the melting processes and decreasing waste. Strategies like die casting and investment spreading permit exact material usage, minimizing excess and scrap.

In addition, several foundries are purchasing renewable resource resources to power operations, further lowering their carbon footprint. Carrying out energy management systems makes it possible for shops to monitor and improve energy usage, guaranteeing they operate at peak performance.

Future Patterns in Lightweight Production Solutions

Exactly how will emerging innovations shape the future of light-weight manufacturing options? Technologies such as innovative materials, automation, and additive manufacturing are readied to redefine production procedures. The integration of wise manufacturing innovations, including the Net of Points (IoT) and fabricated intelligence (AI), will make it possible for real-time monitoring and optimization, boosting effectiveness and lowering waste.

As sustainability proceeds to be an extremely important issue, lightweight remedies will increasingly concentrate on reusing and recycling materials, aligning with round economic climate principles. This evolution in lightweight production will certainly not only enhance product efficiency yet additionally add to environmental goals, guaranteeing that the industry remains competitive in a quickly transforming market landscape.

Often Asked Inquiries

Exactly How Do Light Weight Aluminum Foundries Make Certain Quality Assurance in Production?

Aluminum shops guarantee quality assurance in production through extensive testing, standard procedures, and continual tracking - Aluminum Foundry. They implement innovative technologies and skilled workers to maintain consistency, minimize issues, and meet industry standards throughout the production procedureWhat Are the Main Tests Dealt With by Aluminum Foundries?

Light weight aluminum factories face difficulties such as varying basic material expenses, keeping manufacturing effectiveness, ensuring consistent high quality, adjusting to technical developments, and meeting ecological regulations, all of which effect their total operational efficiency and competitiveness on the market.How Does Light Weight Aluminum Recycling Effect Shop Procedures?

Light weight aluminum reusing considerably boosts shop procedures by reducing resources expenses, lessening energy usage, and reducing ecological effect. This lasting practice enables factories to boost efficiency while satisfying boosting need for light-weight, high-performance light weight aluminum items.What Abilities Are Needed for Workers in Aluminum Foundries?

Employees in light weight aluminum foundries need abilities in metallurgy, machining, quality control, and safety and security methods. Proficiency in running equipment, understanding alloy properties, and problem-solving are likewise essential for effective manufacturing and maintaining high safety and security requirements.How Do Aluminum Foundries Deal With Waste Management?

Aluminum shops manage waste through recycling scrap steel, making use of efficient waste partition strategies, and adhering to environmental website policies. They execute lasting practices to reduce garbage dump payments, making sure that hazardous materials are dealt with responsibly.Aluminum shops greatly contribute to the advancement of lightweight manufacturing options. Recent innovations in light weight aluminum spreading technologies are transforming the production landscape, especially in the production of lightweight elements. While light weight aluminum elements have long been used in various sectors, their flexibility and light-weight properties continue to drive ingenious applications across industries such as vehicle, aerospace, and building. Additionally, the electrical and electronics markets profit from aluminum's conductivity and lightweight nature, using it in electrical wiring, rooms, and heat sinks. The aluminum shop market plays a critical duty in advertising sustainability and energy efficiency, specifically as demand for lightweight components continues to grow throughout various fields.

Report this wiki page